Project DRIVE: Phase 1 Feasibility & Feed

Overview

Optimus is part of a consortium which were awarded BEIS funding to take Project DRIVE from concept & feasibility through to FEED.

The consortium is made up of Mission Zero Technologies, O.C.O and Optimus. Project DRIVE was 1 of 24 projects awarded the £300k funding as part of the BEIS Greenhouse Gas Removal Competition. Mission Zero Technologies own the technology itself, having tested it on a lab bench. Optimus is bringing our expertise and engineering experience to aid the development whilst O.C.O. uses CO2 in manufactured limestone and could become one of the potential buyers of the captured CO2. We believe this is a step in the right direction in overcoming complex issues currently seen in the DAC technology development space.

As part of the consortium working on Project DRIVE, Optimus used our experience in multi-discipline engineering to aid the early development of a new, green carbon capture technology, from FEED to detailed design. Phase 1 of the project involves progressing the technology through early development, feasibility and FEED.

The Process

The core challenge of Project DRIVE was the new technology it deals with, requiring our experienced engineers to use existing knowledge in new ways.

To progress the technology through early development we employed the FEL methodology.

- FEL 1: Concept Eng - Involved learning from the Client/MZT. Understand the process and science. What are the critical parts of the system, and how are they integrated and linked? Relayed all the learning back to MZT in process documents. e.g. BoD, PDF.

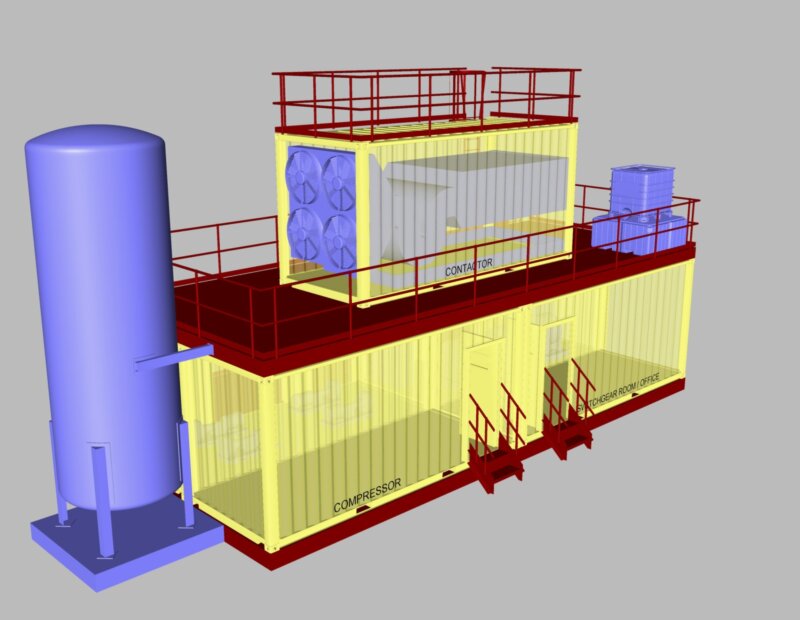

- FEL 2: Feasibility Eng - First design of the plant. Sizing calculations are done, and initial equipment investigation for physical sizing and weight. The 3D layout of the plant was created. In the iterative process and the team learn and refine the design.

- FEL 3: FEED - Based on FEL 2, FEED level engineering was carried out by a multi-discipline team to design the plant and CAPEX estimating

Existing carbon capture methods required extreme heating during the process, increasing its energy demand. However, the process involved with Project DRIVE does not require heating, addressing one of the current development challenges.

The Results

We successfully delivered on time and within budget to both MZT and BEIS. The challenge here was a lack of design definition however this is to be expected when developing new technology. Ultimately, Phase 1 was submitted in application for Phase 2 where Project DRIVE was successful in being awarded further funding.