Abandonment of Storage Cells and Rundown Systems (ASCARS)

Overview.

Optimus were tasked with undertaking an integrity driven SELECT phase study by a regular client in the UKCS. This project looked to assess the feasibility of abandoning an existing rundown line system serving the underwater storage cells of a concrete Gravity Base System (GBS) platform. The rundown system is comprised of four import lines and associated export branches, each with associated manifolds, pumps, valves, and instrumentation. It also included a series of separate smaller diameter vent lines. The scope was broadly split into two parts; Enabling works and Isolation works.

Scope & Challenges.

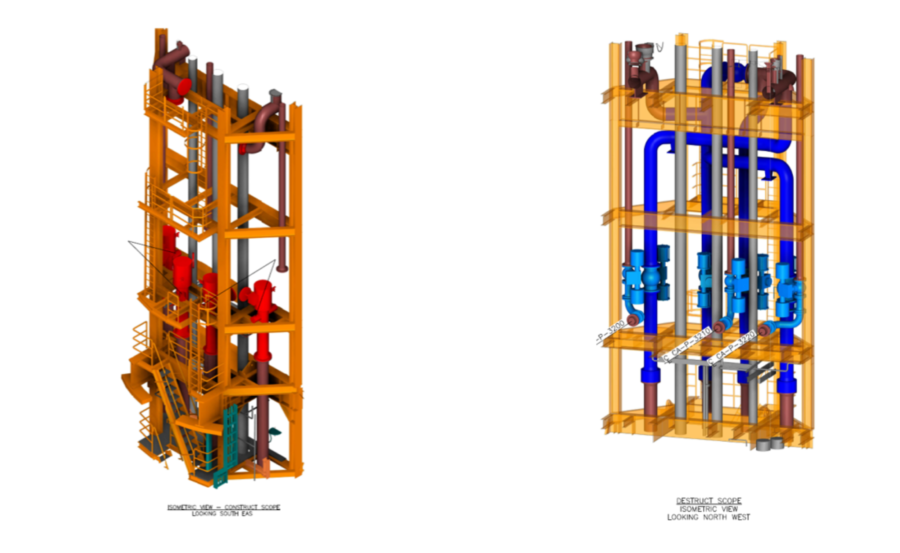

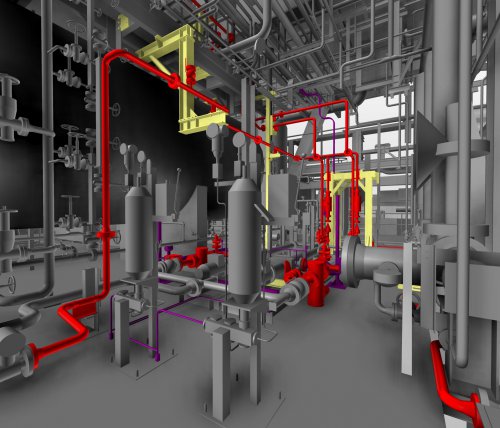

The enabling works involved isolating the rundown system from the live topsides process facilities, before creating new access points in the lines. This included the procurement of four new 16” valves, identified early on as long lead items. The enabling works were intended to facilitate separate scopes (by others) to remove the residual hydrocarbons from the storage tanks, and to undertake the invasive investigate work required to provide assurance of the success of this operation.

The isolation works centered on the provision of temporary and permanent isolations in all associated lines within the system, including: import; export; and vent lines, of varying diameter and accessibility. A notable challenge was in the access and geometry of the system, as the desired set point of the proposed isolation was at a point in the line which externally is normally inaccessible. Additionally, the line geometry includes a 90 degree 1.5D bend, as well as multiple diameter changes along its length from the available access point, meaning any solution had to be remotely deployable. This part of the scope was quickly understood to be more technically challenging hence why it was decoupled from the enabling works. In all cases, it was vital that the proposed works minimised the impact to existing production, nor could they predetermine or influence the eventual decommissioning strategy for the platform.

Delivery.

Throughout this scope, Optimus were required to work closely with other engineering contractors, each of whom had responsibility for a suite of interfacing workscopes. Optimus undertook a multi-discipline survey of the prospective work areas within the leg area, completing 3D laser scanning coupled with manual survey means. Entry to this part of the platform required specialist confined space entry training for the team and careful planning and execution of the survey itself.

A selection of specialist vendors were approached for comment in discrete areas, with some being engaged further to make detailed contributions. As stated above, identified long lead items were requisitioned by Optimus at this early phase via the clients own supply chain, with these items being package managed by our technical team through to delivery.

Our deliverables included study reports and technical notes, which included; comparative assessment of options, identification of recommendations; definition of the scope going into the next phase; cost estimates for future phases, schedule / sequence of activities coupled with a RACI matrix; risks and opportunities highlighted; and a suite of supporting sketches and drawings to communicate the proposals. This successful execution of this work scope phase led to the award of the DEFINE phase scope for the enabling works.